Properties of Glassware and Plasticware

Properties of Glassware

Chemical Composition: Our glassware is manufactured from low-expansion Type 1, Class A Borosilicate 3.3 glass that complies with ASTM E438 Standard Specification for Glasses in Laboratory Apparatus. It is low alkali glass with a typical chemical composition of approximately 81% silica, 13% boric oxide, 4% sodium oxide, and 2% aluminum oxide. It is virtually free of magnesia-lime-zinc group, and contains only traces of heavy metals.

Thermal Properties: Borosilicate glass has a low coefficient of thermal expansion. Therefore, the thermal stresses under a given temperature gradient are low, and the glass can withstand higher temperature gradients as well as sudden temperature changes / thermal shocks. However, even minute scratching of glass surface can reduce its thermal resistance. The 'Strain Point' (about 500°C) is generally recommended as the maximum safe operating temperature for United glassware. The glass may acquire permanent stresses upon cooling if it is heated above 500°C. Our glassware is annealed in modern ovens under strictly controlled conditions to ensure minimal residual stress.

Chemical Durability: Our glassware is highly resistant to water, neutral and acid solutions, concentrated acids and their mixtures, as well as to chloride, bromine, iodine, and organic matters. Even during extended period of reaction and at temperatures above 100°C, its chemical resistance exceeds that of most metals and other materials. Our glassware can withstand repeated dry and wet sterilization and offers good resistance against various chemicals, except for hydrofluoric acid, hot phosphoric acid and alkaline solutions.

Optical Properties: Our glassware has a clear and colorless appearance, and shows no noticeable absorption in the visible region of the spectrum.

Safety: Treated with proper care, our glassware will offer long-term, reliable service in the laboratory. Please contact us for detailed recommendations regarding heating and cooling, mixing and stirring, vacuum and pressure, cleaning, and safety precautions that must be followed while using glassware.

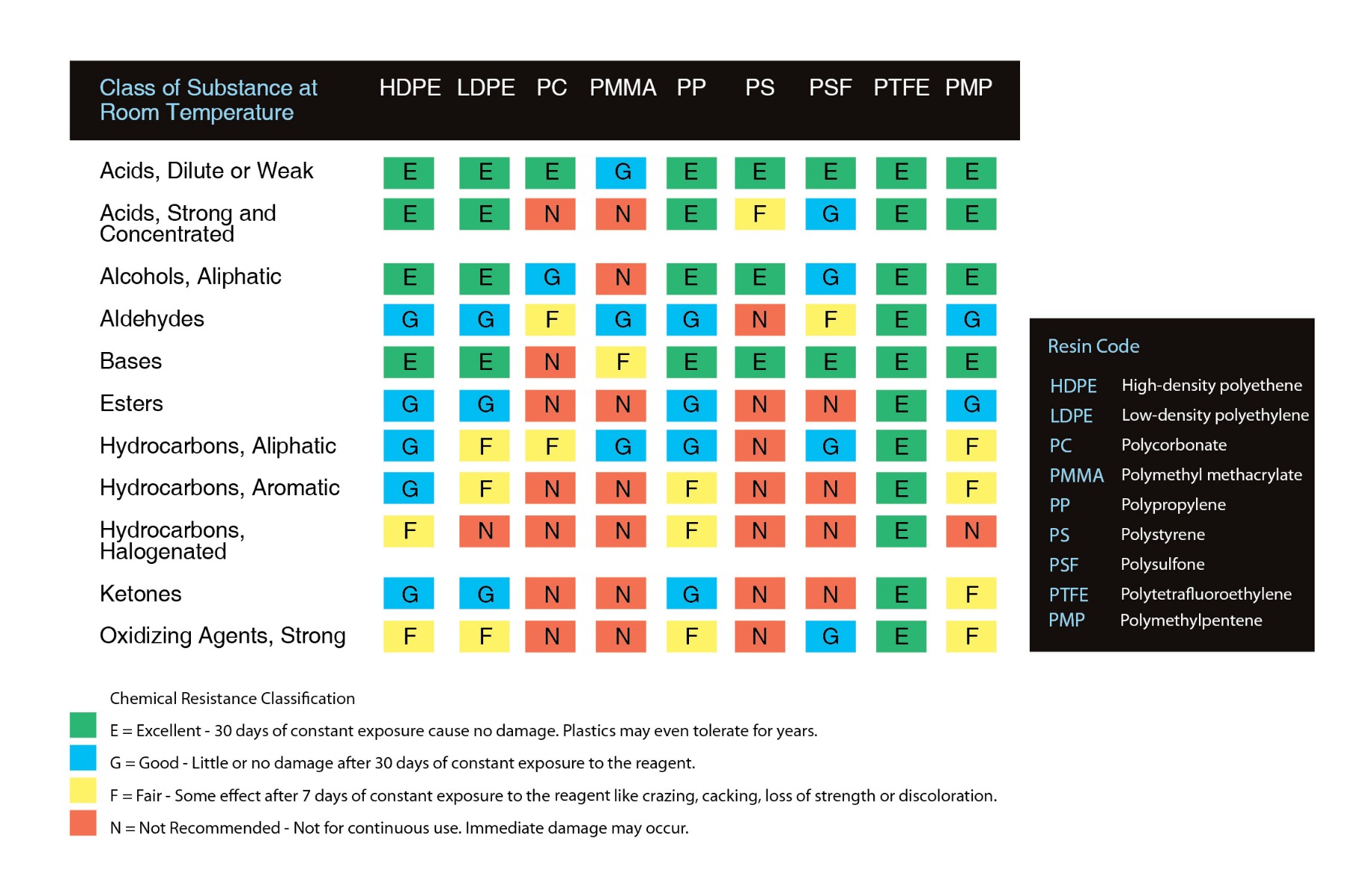

Physical Properties of Plastic Labware

Our plastic labware is manufactured from high-quality resins. Treated with proper care, our plasticware will offer long-term satisfactory service in the laboratory.

Please refer to the chart below for physical properties of our plasticware.

|

Resin |

Maximum Use Temperature (°C) |

Brittleness Temperature (°C) |

Transparency |

Autoclavable* |

|

High Density Polyethylene (HDPE) |

120 |

-100 |

Translucent |

No |

|

Low Density Polyethylene (LDPE) |

80 |

-100 |

Translucent |

No |

|

Polycarbonate (PC) |

135 |

-135 |

Clear |

Yes |

|

Acrylic (PMMA) |

50 |

20 |

Clear |

No |

|

Polymethylpentene (PMP) |

175 |

20 |

Clear |

Yes |

|

Polypropylene (PP) |

135 |

0 |

Translucent |

Yes |

|

Polystyrene (PS) |

90 |

20 |

Clear |

No |

|

Polytetrafluoroethylene (PTFE) |

270 |

-200 |

Opaque |

Yes |

|

Polyvinyl Chloride (PVC) |

70 |

-30 |

Clear |

No |

* Autoclave at 121°C, 15 psi for 20 minutes. Clean and rinse item with distilled water before autoclaving. Certain chemicals which have no appreciable effect on resins at room temperature may cause deterioration at autoclaving temperatures.